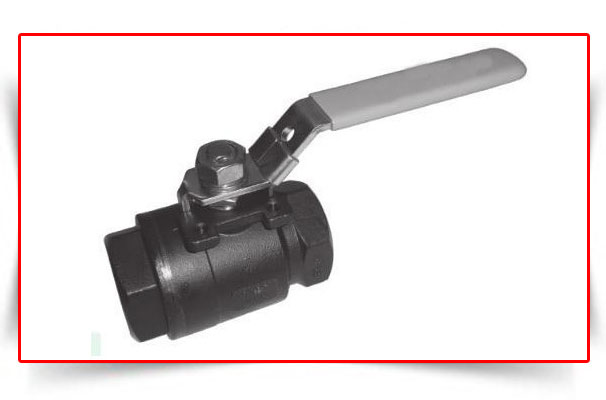

Specification : ASTM A351 / A494 & ASME SA351 / SA494

Type: Ball Valves, Needle Valves, Check Valves, Non Return Valves, 2 Way Manifold, 3 Way Manifold, 5 Way Manifold

Size : 1/8 to 1”, Custom Sizes available on request

Working Pressure : Up to 6000 PSIG, valves are also available that can handle higher pressure

End Connection : Male and Female NPT, BSPT, Socket Weld (SW) or Dual Ferrule Tube Connections, Male to Female, Female to Female

Temperature Rating : PTFE 450F,(232C)/Grafoil 700 F(371C)

Flow Pattern : Straight/ Angle

Connection : Thread, Weld or Tube End

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Specification : ASTM A351 / A494 & ASME SA351 / SA494

Specification : ASTM A351 / A494 & ASME SA351 / SA494

Type: Ball Valves, Needle Valves, Check Valves, Non Return Valves, 2 Way Manifold, 3 Way Manifold, 5 Way Manifold

Size : 1/8 to 1”, Custom Sizes available on request

Working Pressure : Up to 6000 PSIG, valves are also available that can handle higher pressure

End Connection : Male and Female NPT, BSPT, Socket Weld (SW) or Dual Ferrule Tube Connections, Male to Female, Female to Female

Temperature Rating : PTFE 450F,(232C)/Grafoil 700 F(371C)

Flow Pattern : Straight/ Angle

Connection : Thread, Weld or Tube End

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

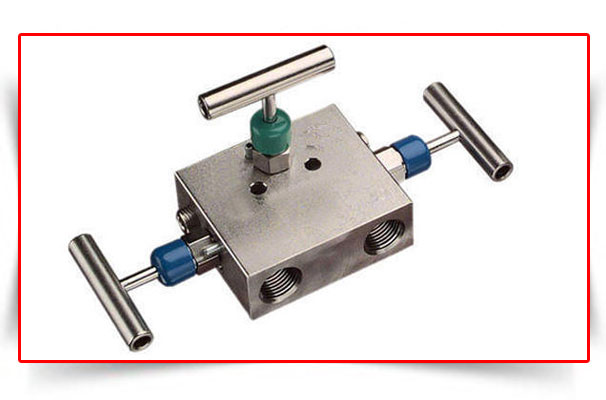

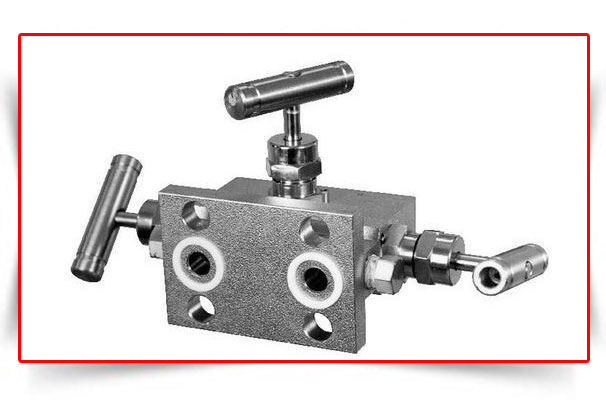

Product Name: Manifold Valves

Manifold Valves available Size: : 1/8 to 1”, Custom Sizes available on request

Connection : Thread, Weld or Tube End

Flow Pattern: : Straight/ Angle

Power: : Manual

End Connection: : Male and Female NPT, BSPT, Socket Weld (SW) or Dual Ferrule Tube Connections, Male to Female, Female to Female

Working Pressure: Up to 6000 PSIG, Manifold Valves are also available that can handle higher pressure

Temperature Rating:

PTFE 450F,(232C)/ Grafoil 700 F(371C)

Manifold Valves Material: : SS 316, SS 304, C.S, F11, Hastelloy, Monel 400, Duplex

Stem: : Vee Steam is standard for pressure tightness even at elevated temperatures. Regulating Stem and Soft-seat Stem are optional

Testing: : 100% Factory Tested

Testing and Inspection: : Manufacturer Test Certificate as per EN 10204 / 3.1, Raw Materials Certificate, Third Party Inspection, Buyer Inspection

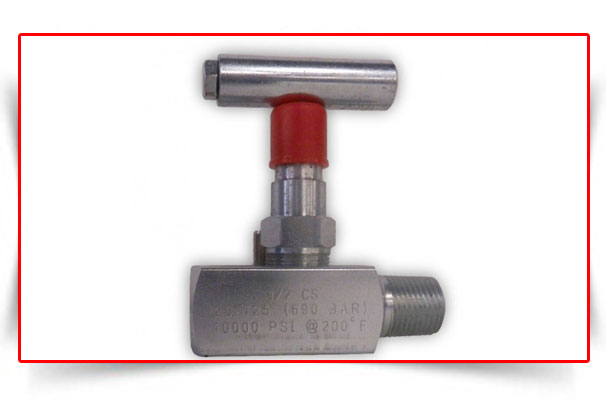

Product Name: Needle Valves

Needle Valves Design: Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

Needle Valves available Size: 1/8 to 1”, Custom Sizes available on request

Connection Thread, Weld or Tube End

Flow Pattern: Straight/ Angle

Power: Manual

End Connection: Male and Female NPT, BSPT, Socket Weld (SW) or Dual Ferrule Tube Connections, Male to Female, Female to Female

Working Pressure:

Up to 6000 PSIG, Needle Valves are also available that can handle higher pressure

Temperature Rating:

PTFE 450F,(232C)/ Grafoil 700 F(371C)

Needle Valves Material: SS 316, SS 304, C.S, F11, Hastelloy, Monel 400

Stem: Vee Steam is standard for pressure tightness even at elevated temperatures. Regulating Stem and Soft-seat Stem are optional

Testing: 100% Factory Tested

Specialized Needle Valves we produce:

Testing and Inspection: Manufacturer Test Certificate as per EN 10204 / 3.1, Raw Materials Certificate, Third Party Inspection, Buyer Inspection

Standards : API 600/BS1414, API 598/BS EN 12266-1, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34

Type: Ball Valves, Needle Valves, Check Valves, Non Return Valves, 2 Way Manifold, 3 Way Manifold, 5 Way Manifold

Size : 1/8 to 1”, Custom Sizes available on request

Working Pressure : Up to 6000 PSIG, valves are also available that can handle higher pressure

End Connection : Male and Female NPT, BSPT, Socket Weld (SW) or Dual Ferrule Tube Connections, Male to Female, Female to Female

Temperature Rating : PTFE 450F,(232C)/Grafoil 700 F(371C)

Pressure rating : 150#,300#,600#,800#,1500#

Standards : API 600/BS1414, API 598/BS EN 12266-1, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34

Type: Ball Valves, Needle Valves, Check Valves, Non Return Valves, 2 Way Manifold, 3 Way Manifold, 5 Way Manifold

Size : 1/8 to 1”, Custom Sizes available on request

Working Pressure : Up to 6000 PSIG, valves are also available that can handle higher pressure

End Connection : Male and Female NPT, BSPT, Socket Weld (SW) or Dual Ferrule Tube Connections, Male to Female, Female to Female

Temperature Rating : PTFE 450F,(232C)/Grafoil 700 F(371C)

Pressure rating : 150#,300#,600#,800#,1500#

Product Name: Manifold Valves

Manifold Valves available Size: 1/8 to 1”, Custom Sizes available on request

Connection Thread, Weld or Tube End

Flow Pattern: Straight/ Angle

Power: Manual

End Connection: Male and Female NPT, BSPT, Socket Weld (SW) or Dual Ferrule Tube Connections, Male to Female, Female to Female

Working Pressure: Up to 6000 PSIG, Manifold Valves are also available that can handle higher pressure

Temperature Rating:

Manifold Valves Material: SS 316, SS 304, C.S, F11, Hastelloy, Monel 400

Stem: Vee Steam is standard for pressure tightness even at elevated temperatures. Regulating Stem and Soft-seat Stem are optional

Testing: 100% Factory Tested

Testing and Inspection: Manufacturer Test Certificate as per EN 10204 / 3.1, Raw Materials Certificate, Third Party Inspection, Buyer Inspection

Product Name: Needle Valves

Needle Valves Design: Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design

Needle Valves available Size: 1/8 to 1”, Custom Sizes available on request

Connection Thread, Weld or Tube End

Flow Pattern: Straight/ Angle

Power: Manual

End Connection: Male and Female NPT, BSPT, Socket Weld (SW) or Dual Ferrule Tube Connections, Male to Female, Female to Female

Working Pressure:

Up to 6000 PSIG, Needle Valves are also available that can handle higher pressure

Temperature Rating:

PTFE 450F,(232C)/ Grafoil 700 F(371C)

Needle Valves Material: SS 316, SS 304, C.S, F11, Hastelloy, Monel 400

Stem: Vee Steam is standard for pressure tightness even at elevated temperatures. Regulating Stem and Soft-seat Stem are optional

Testing: 100% Factory Tested

Specialized Needle Valves we produce:

Testing and Inspection: Manufacturer Test Certificate as per EN 10204 / 3.1, Raw Materials Certificate, Third Party Inspection, Buyer Inspection